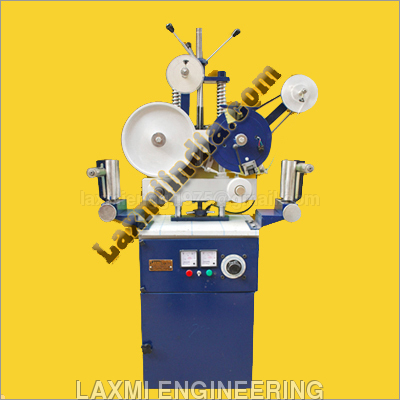

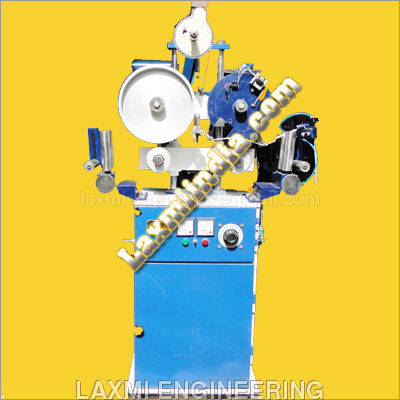

Sequential Cable Marking Machines

Price 65000.0 INR/ Piece

Sequential Cable Marking Machines Specification

- Marking Area

- 110 x 110 mm / 175 x 175 mm

- Marking Speed

- 7000 mm/s

- Condition

- New

- Laser Type

- Fiber Laser

- CNC

- Yes

- Cooling Mode

- Air Cooling

- Control Software

- EZCAD

- Accuracy

- 0.01 mm

- Power

- 20W / 30W / 50W

- Dimensions

- 650 x 450 x 600 mm

Sequential Cable Marking Machines Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cheque, Cash in Advance (CID)

- Delivery Time

- 1 Days

- Packaging Details

- Packed in wooden boxes.

- Main Domestic Market

- All India

About Sequential Cable Marking Machines

Owing to our firm commitment and desiccation, we are able to manufacture and supply our Sequential Meter Marking Machines (New Matic ). These machines are integrated with the hot stumping foil that is used for marking cables in a sequential manner of 10 inch pressure pipe machines. Our Sequential Meter Marking Machines (New Matic ) are extensively applicable for marking the information of cables specifications and meter marking over pvc sheathed cables.

Features:

- Accuracy in operations

- Easy to operate and maintain

- Long operational life

Further Details:

the meter head of this machinery is of four numerical digits.

Features

-

Operated by cables movement. (range 10mm to 100mm diameter cable)

-

Pneumatic loaded cable guides.

-

Accuracy range +1mm.

-

Can be operated on line or rewinding line.

-

Range of line speed is up to 50meter per minute.

-

Provision for instant zero setting

High-Precision Laser Marking for Cables

Engineered for precision, our sequential cable marking machine enables detailed, legible marks on a variety of cable materials. Featuring an advanced fiber laser system, it supports versatile industrial applications, ensuring each cable is marked with unmatched accuracy and speed.

Effortless Operation with EZCAD Software

Our machine is integrated with user-friendly EZCAD control software, allowing operators of various skill levels to customize marking parameters efficiently. The intuitive interface streamlines the process, making setup, operation, and ongoing production both simple and consistent.

Reliable and Energy-Efficient Design

Built with reliable air-cooling technology, the machine ensures consistent performance while minimizing energy consumption. Its compact build (650 x 450 x 600 mm) allows for easy installation in diverse industrial environments without compromising on output power or marking speed.

FAQs of Sequential Cable Marking Machines:

Q: How does the sequential cable marking machine operate?

A: The machine uses fiber laser technology, activated by the EZCAD control software, to mark cables sequentially with exceptional accuracy. You simply set your marking parameters in the software, position the cable, and the system performs high-speed, precise marking according to your specifications.Q: What are the typical applications for this cable marking machine?

A: This machine is ideal for marking serial numbers, logos, codes, or graphics on a wide range of cable types. Its widely used by cable manufacturers, suppliers, and exporters for traceability, brand identification, and product categorization.Q: When is it beneficial to choose air cooling over other cooling methods?

A: Air cooling is recommended for environments where maintenance needs to be minimal and water supply may be impractical. It extends machine longevity and maintains steady performance, particularly important in continuous production settings.Q: Where can the cable marking machine be installed?

A: With compact dimensions (650 x 450 x 600 mm), the machine can be easily placed on a workstation or integrated into existing production lines in manufacturing plants, warehouses, or workshops.Q: What is the process for marking cables with this machine?

A: First, the operator loads the desired data into the EZCAD software and places the cable under the laser. The fiber laser then marks the cable accurately according to the set parameters, at speeds up to 7000 mm/s, covering the specified marking area.Q: How does fiber laser marking benefit cable manufacturing businesses?

A: Fiber laser marking ensures permanent, high-resolution results with little maintenance, reduced operational costs, and significant productivity gains. It eliminates consumables and minimizes downtime, improving efficiency and overall product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Marking Machines Category

Sequential Marking Machine

Price 65000 INR

Minimum Order Quantity : 01 Piece

CNC : Yes

Dimensions : 660 x 160 x 420 mm

Laser Type : Fiber Laser

Marking Speed : 7000 mm/s

Send Inquiry

Send Inquiry