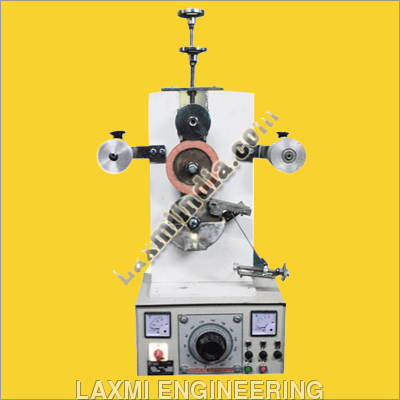

Sleeve Pipe Printing Machine

MOQ : as per requirement Unit

Sleeve Pipe Printing Machine Specification

- Type

- Sleeve Pipe Printing Machine

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Letterpress

- Ink Type

- Water Based Ink

- Color Management

- Cyan, Magenta, Yellow, Black

- Control System

- PLC Control

- Power

- 3.5 kW

- Size

- Standard

- Width

- Up to 350 mm

- Weight (kg)

- 1200 kg

- Dimension (L*W*H)

- 2500 x 1200 x 1600 mm

Sleeve Pipe Printing Machine Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 1 Days

- Packaging Details

- Packed in wooden boxes.

- Main Export Market(s)

- Middle East, Australia, Eastern Europe, North America, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Sleeve Pipe Printing Machine

With the help of our modern infrastructural facilities, we are capable of manufacturing and exporting the advanced gamut of Sleeve Pipe Printing Machine. These machines are considered suitable for pipe printing activities. We design and develop these machines in compliance with the international standards of quality and durability. After production process, we inspect the Sleeve Pipe Printing Machine on varied defined parameters in order to ensure longer service life.

Features:

- Low operational cost

- Fine and reliable functioning

- Optimum quality parameters

Further Details:

- 6 Inch Printing Wheel

- 3 mm Slim: 32 mm slim

Advanced Printing Technology

Our sleeve pipe printing machine utilizes letterpress technology combined with water-based inks to achieve vibrant, long-lasting print results. This approach ensures environmentally friendly operations while delivering superior quality and clarity on every sleeve pipe.

Fully Automated & Computerized Controls

Equipped with a sophisticated PLC control system, the machine automates the entire printing process, reducing manual interventions and improving productivity. Computerized configuration enables smooth monitoring and adjustments to ensure consistent output and lowest possible downtime.

Robust Construction and High Versatility

Built from premium mild steel, this robust machine is designed to withstand rigorous industrial use. Supporting sleeve widths up to 350 mm, it caters to a wide range of printing requirements within the industry, all while maintaining accuracy and speed.

FAQs of Sleeve Pipe Printing Machine:

Q: How does the sleeve pipe printing machine operate?

A: The sleeve pipe printing machine functions through an automated PLC-controlled system, using letterpress plates and water-based inks. Once set up, the operator simply loads the sleeve pipe and programs the printer, which then automatically manages the ink application and color management for consistent, high-quality results.Q: What types of prints and colors can be achieved with this machine?

A: The machine supports full-color printing using cyan, magenta, yellow, and black, ensuring detailed and vibrant prints. Its letterpress technology delivers sharp, clear images and text suitable for a variety of sleeve pipe applications.Q: When is the ideal scenario to use this printing machine?

A: This machine is particularly effective for high-volume or continuous sleeve pipe production lines, where automation and quality are critical. It streamlines operations, reduces manual errors, and boosts throughput for manufacturers and suppliers.Q: Where is this sleeve pipe printing machine manufactured and supplied?

A: The machine is manufactured and exported from India by reputed manufacturers and suppliers, making it accessible to both domestic and international markets seeking reliable pipe printing solutions.Q: What is the process for setting up and operating the machine?

A: To begin, users need to configure the machines PLC settings, install the desired letterpress plate, and select the appropriate water-based ink. The system handles the registration and color alignment, ensuring optimal print output with minimal manual supervision.Q: What are the main usage benefits of this sleeve pipe printing machine?

A: Key benefits include reduced labor requirements, high-speed operation, consistent print quality, and environmentally friendly water-based inks. Its robust mild steel construction ensures longevity and minimal maintenance, optimizing operational costs.Q: How does the machine enhance production efficiency for manufacturers?

A: With its automatic, computerized functions and fast setup, the machine significantly cuts production times. The accurate control system helps minimize waste and ensures uniform quality, allowing manufacturers to fulfill large orders reliably and cost-effectively.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry