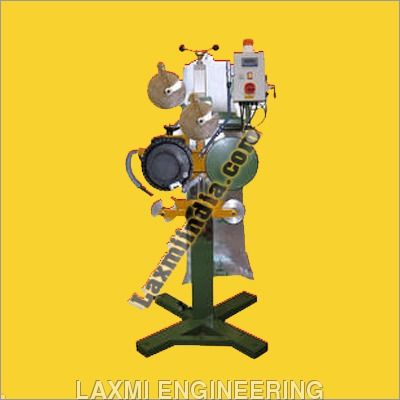

Garden Pipe Printing Machine

Garden Pipe Printing Machine Specification

- Type

- Garden Pipe Printing Machine

- Material

- Mild Steel

- Printing Speed

- Up to 60 meter/minute

- Computerized

- No

- Automatic Grade

- Automatic

- Plate Type

- Letterpress

- Ink Type

- Water Based Ink

- Color Management

- Single Color

- Control System

- Panel Board Control

- Power

- 2.2 KW

- Size

- Standard

- Width

- Customizable

- Weight (kg)

- 350

- Dimension (L*W*H)

- 1800 x 750 x 1500 mm

Garden Pipe Printing Machine Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 1 Days

- Packaging Details

- Packed in wooden boxes.

- Main Export Market(s)

- Middle East, Eastern Europe, Western Europe, Africa, Central America, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About Garden Pipe Printing Machine

Empowered by the state-of-the-art infrastructure unit, we are able to manufacture and supply a huge stock of Garden Pipe Printing Machine. Our finely assembled machines are helpful in providing fast and accurate printing facilities to the garden pipes. All our machines are highly durable and hence provide optimum performance for long time frame. Additionally, we deliver our Garden Pipe Printing Machine to the customers at most competitive prices.

Features:

- Less power consumption

- Easy to operate

- Noiseless operation

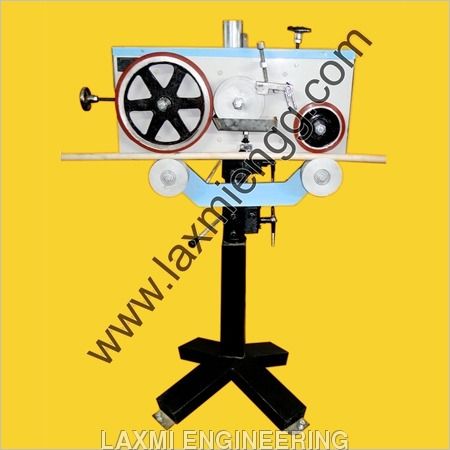

High-Speed, Industrial Performance

Engineered for rigorous industrial environments, this pipe printing machine offers printing speeds up to 60 meters per minute. Its automatic features combined with continuous pipe feeding allow uninterrupted operation, boosting productivity for manufacturers and suppliers who require quick and consistent printing on garden and flexible pipes.

User-Friendly Control and Maintenance

Operation is made simple with a panel board control system and requires only one operator. The adjustable pipe guide mechanism accommodates pipes of 12 mm to 110 mm in diameter. Manual roller cleaning keeps the machine in optimal condition, while the low noise output ensures a comfortable workplace.

Precision Branding and Marking

With a printing width capability of up to 100 mm and a single-color, water-based ink system, this machine delivers crisp, clear markings and branding. The sturdy, powder-coated mild steel frame ensures durability and longevity, making it ideal for industrial-scale export, manufacturing, and supply.

FAQs of Garden Pipe Printing Machine:

Q: How does the continuous feeding system on the Garden Pipe Printing Machine work?

A: The continuous pipe feeding mechanism enables seamless and uninterrupted insertion of garden or flexible pipes into the printing area, ensuring efficient operation. This design maximizes throughput and maintains consistent pipe alignment for high-quality print results.Q: What process is used for printing on the pipes?

A: This machine employs letterpress technology with a single-color, water-based ink. Pipes are guided through the printing system, where ink is transferred via a letterpress plate, producing clear and lasting markings suitable for industrial branding and identification.Q: When should the manual roller cleaning system be used?

A: The manual roller cleaning system should be used at regular intervals or whenever print quality declines. Frequent cleaning prevents ink buildup on the rollers, ensuring sharp, consistent prints and prolonging the machines operational lifespan.Q: Where can this machine be installed, and what are its space requirements?

A: Designed for industrial settings, the machine requires a standard installation area sized approximately 1800 mm (L) x 750 mm (W) x 1500 mm (H). It can be placed in manufacturing units, supply warehouses, or export facilities with access to a 220V/380V, 50Hz power source.Q: What benefits does this machine offer for pipe marking and branding?

A: This printing machine provides fast, reliable, and uniform branding or product information on pipes. Its low noise, single-operator requirement, and robust construction reduce labor costs and enhance workplace comfort, supporting efficient business operations.Q: How is the printing width and pipe diameter adjusted on the machine?

A: The adjustable pipe guide mechanism allows operators to set the machine for different pipe diameters within the range of 12 mm to 110 mm and customize the printing width up to 100 mm, accommodating various pipe sizes with ease.Q: What type of inks are compatible with this garden pipe printing machine?

A: The machine is designed specifically for use with water-based inks, providing a safer and environmentally friendly option for high-speed, single-color industrial pipe printing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Printing Machines Category

10 Inches PVC Pipe Printing Machine

Price 50000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 3 Phase, 440V, 2.5 kW Volt (v)

Dimension (L*W*H) : 2500 mm x 900 mm x 1450 mm Millimeter (mm)

Weight (kg) : Approx. 650 kg Kilograms (kg)

Width : Adjustable up to 10 inches Inch (in)

PVC Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Power : 2.5 kW

Dimension (L*W*H) : 2200 mm x 600 mm x 1400 mm

Weight (kg) : Approx. 400 kg

Width : 600 mm

Hot Embossing Machine

Minimum Order Quantity : as per requirement Unit

Power : 1.5 kW

Dimension (L*W*H) : 1000 x 500 x 1300 mm

Weight (kg) : Approx 120 kg

Width : 500 mm

One Meter Pipe Printing Machine

Price 52000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 220V/50Hz Volt (v)

Dimension (L*W*H) : 2200 mm x 800 mm x 1300 mm Millimeter (mm)

Weight (kg) : Approx. 400 kg Kilograms (kg)

Width : Adaptable Up to 120 mm Pipe Millimeter (mm)

Send Inquiry

Send Inquiry