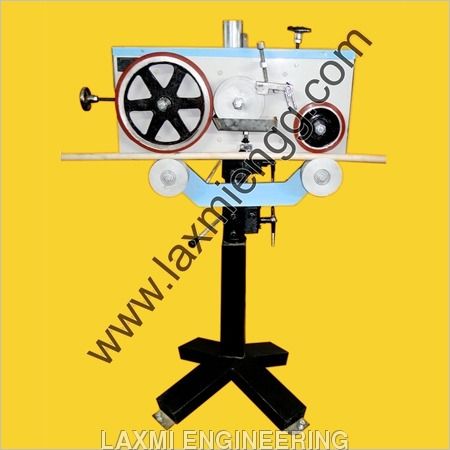

PVC Pipe Printing Machine

PVC Pipe Printing Machine Specification

- Type

- PVC Pipe Printing Machine

- Material

- Mild Steel

- Capacity

- Up to 200 pipes/hour

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Rotary Plate

- Ink Type

- Solvent Based Ink

- Color Management

- Single/Double Color

- Control System

- PLC Controlled

- Working Temperature

- 5C 45C

- Power

- 2.5 kW

- Size

- Standard

- Width

- 600 mm

- Weight (kg)

- Approx. 400 kg

- Dimension (L*W*H)

- 2200 mm x 600 mm x 1400 mm

PVC Pipe Printing Machine Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 1 Days

- Packaging Details

- Packed in wooden boxes.

- Main Export Market(s)

- Middle East, Eastern Europe, Africa, Central America, Australia, South America, Western Europe, Asia, North America

- Main Domestic Market

- All India

About PVC Pipe Printing Machine

Empowered by the high-tech production facilities, we are capable of manufacturing and exporting a wide array of PVC Pipe Printing Machine. These machines are perfectly assembled with braided hose ranging from 12 mm to 225 mm that is fitted with the gear box useful for prominence and high speed. Our offered PVC Pipe Printing Machine is well integrated with 8 inch printing wheel that makes these suitable for PVC pipes printing.

Features:

- Ensure quality printing

- Optimum speed

- Accuracy in operations

Advanced Technology for Precision Printing

This PVC Pipe Printing Machine is equipped with PLC controls and computerized systems, supporting reliable and consistent operation. The rotary plate design, along with solvent-based ink and single or double color options, guarantees clear, durable print quality on every pipe, meeting stringent industry requirements.

High Efficiency and Robust Construction

Constructed from mild steel, the machine can print up to 200 pipes per hour, optimizing productivity for manufacturers and suppliers. Its automatic operation reduces manual intervention, while the solid build ensures long-term reliability and a stable printing process, even during continuous use.

Versatile Applications and User-Friendly Operation

Suitable for various production settings, this machine fits standard installations and accommodates different working temperatures from 5C to 45C. Its user-friendly interface, powered by a PLC control system, makes it easy for operators of all experience levels to manage and maintain the machine.

FAQs of PVC Pipe Printing Machine:

Q: How does the PVC Pipe Printing Machine operate for efficient printing?

A: The machine automatically feeds PVC pipes and prints them using a rotary plate system and solvent-based inks. It is PLC controlled, enabling precise and consistent operation at speeds up to 200 pipes per hour, minimizing manual intervention and maximizing efficiency.Q: What types of PVC pipes can be printed with this machine?

A: This machine is designed for all standard PVC pipes that fit within the specified dimension limits. Its adjustable configuration accommodates various pipe diameters, making it ideal for manufacturers with diverse product lines.Q: Where can the PVC Pipe Printing Machine be installed and used?

A: The machine is suitable for use in manufacturing plants, industrial workshops, and pipe production facilities. Its compact size and standard dimensions (2200 mm x 600 mm x 1400 mm) allow for flexible integration into existing production lines.Q: What is the benefit of using solvent-based inks in the printing process?

A: Solvent-based inks provide excellent adhesion and durability on PVC surfaces. This ensures the printed information remains clear and resistant to environmental exposure, chemicals, and abrasion, extending the lifespan of the print.Q: How is color management handled on this PVC Pipe Printing Machine?

A: The machine supports both single and double color management, allowing you to choose between basic and more complex print designs. This flexibility enhances branding and compliance with labeling standards.Q: What kind of maintenance does this machine require for optimal performance?

A: Regular maintenance consists of cleaning ink passages, checking for clogs, and ensuring the rotary plate and PLC components are functioning smoothly. The robust design reduces the frequency of repairs, ensuring consistent operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Printing Machines Category

10 Inches PVC Pipe Printing Machine

Price 50000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Plate Type : Letterpress

Weight (kg) : Approx. 650 kg Kilograms (kg)

Power : 3 Phase, 440V, 2.5 kW Volt (v)

Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Computerized : Yes

Plate Type : Letterpress

Weight (kg) : Approx. 250 Kg

Power : 220V / 50Hz / 1.5 kW

One Meter Pipe Printing Machine

Price 52000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

Plate Type : Other, Roller Plate

Weight (kg) : Approx. 400 kg Kilograms (kg)

Power : 220V/50Hz Volt (v)

Garden Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Computerized : No

Plate Type : Letterpress

Weight (kg) : 350

Power : 2.2 KW

Send Inquiry

Send Inquiry