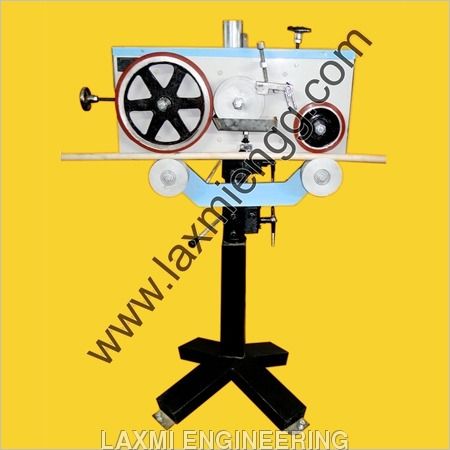

Pipe Printing Machine

Pipe Printing Machine Specification

- Type

- Pipe Printing Machine

- Material

- Mild Steel

- Capacity

- Up to 3500 pipes/hour

- Printing Speed

- Up to 60 meter/min

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Letterpress

- Ink Type

- Quick Drying Ink

- Control System

- PLC Based Control Panel

- Working Temperature

- 5C to 45C

- Power

- 220V / 50Hz / 1.5 kW

- Size

- Medium Scale

- Width

- 650 mm

- Weight (kg)

- Approx. 250 Kg

- Dimension (L*W*H)

- 2100 x 650 x 1500 mm

Pipe Printing Machine Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Packaging Details

- Packed in wooden boxes.

- Main Export Market(s)

- Western Europe, South America, Eastern Europe, Australia, Africa, Central America, Middle East, Asia, North America

- Main Domestic Market

- All India

About Pipe Printing Machine

Being a well-established and highly recognized enterprise, we are engrossed in offering Pipe Printing Machines (8 inch). The offered machines are manufactured using the best quality components and sophisticated technology under the stern supervision of our skilled experts in compliance with international standards. Stringently tested on several parameters prior to dispatch at clients end, our provided machines are used for printing several impressions like ISI marks, license, size, logo and batch number on a pipe. Moreover, these Pipe Printing Machines(8 inch) can be availed by our clients from us at industry leading prices.

Features:

- Hassle free performance

- Longer operational life

- Robustly constructed

- Negligible maintenance

Advanced Printing Technology

Equipped with a letterpress plate type and powered by a PLC-based control panel, this Pipe Printing Machine delivers high-quality, consistent print results. Its automatic operation and computerized controls minimize manual intervention, ensuring high throughput and superior reliability for manufacturers and suppliers.

Versatility and Efficiency

With the ability to process up to 3,500 pipes per hour and print at speeds of up to 60 meters per minute, this machine greatly enhances productivity for pipe manufacturers. Its medium-scale footprint and mild steel construction allow for easy integration into existing production lines without compromising durability or performance.

FAQs of Pipe Printing Machine:

Q: How does the PLC-based control system enhance the pipe printing process?

A: The PLC-based control panel automates and streamlines the operation, providing precise adjustments, error detection, and improved safety. This technology ensures accurate print placement and consistent quality, reducing the need for manual intervention.Q: What type of ink does the Pipe Printing Machine use, and what are its benefits?

A: The machine uses quick drying ink, allowing for faster processing and minimizing smudging or blotting. This makes it ideal for high-speed industrial environments where output quality and turnaround time are essential.Q: When is this Pipe Printing Machine most beneficial to use?

A: It is best utilized in medium-scale manufacturing environments where high output, efficiency, and consistent print quality on pipes are required. Its automation and customizable settings make it suitable for both large and small production batches.Q: Where can this Pipe Printing Machine be installed?

A: Thanks to its medium-scale size and robust design, this machine fits seamlessly into most industrial settings. It is particularly suitable for pipe manufacturing plants and can be easily accommodated due to its compact dimensions and manageable weight.Q: What is the typical process for setting up and operating this machine?

A: Setup involves positioning the machine on a stable surface, connecting it to a 220V power supply, and configuring the control panel. Operators can then load the pipes, select print parameters, and start the automatic printing process using the PLC interface.Q: How is the maintenance of this Pipe Printing Machine managed?

A: Routine maintenance includes cleaning the ink system, inspecting mechanical parts, and checking electronic controls. Mild steel construction and quick-drying ink optimize durability and reduce the need for frequent part replacements.Q: What are the main advantages of using this machine for pipe manufacturers and exporters?

A: Manufacturers and exporters benefit from rapid production rates, reliable print consistency, and streamlined operations. The machines automated features help reduce labor costs, improve product appearance, and enhance overall efficiency for Indian and international markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Printing Machines Category

10 Inches PVC Pipe Printing Machine

Price 50000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Width : Adjustable up to 10 inches Inch (in)

Weight (kg) : Approx. 650 kg Kilograms (kg)

Size : 10 Inches (Printing Capacity)

Computerized : Yes

PVC Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Width : 600 mm

Weight (kg) : Approx. 400 kg

Size : Standard

Computerized : Yes

One Meter Pipe Printing Machine

Price 52000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Width : Adaptable Up to 120 mm Pipe Millimeter (mm)

Weight (kg) : Approx. 400 kg Kilograms (kg)

Size : Compact

Computerized : Yes

Double CPVC Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Width : Adjustable (as per pipe size)

Weight (kg) : Approx. 350 kg

Size : Standard

Computerized : Yes

Send Inquiry

Send Inquiry