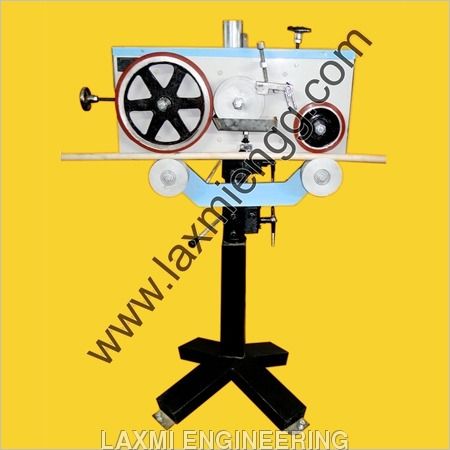

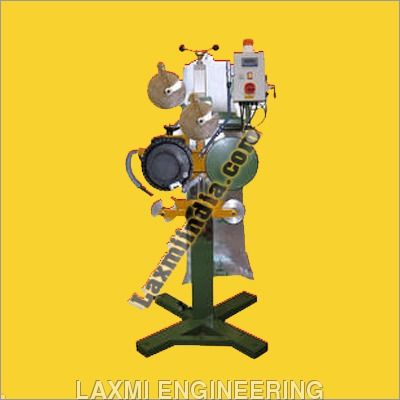

10 Inches PVC Pipe Printing Machine

Price 50000.0 INR/ Unit

10 Inches PVC Pipe Printing Machine Specification

- Type

- PVC Pipe Printing Machine

- Material

- Mild Steel

- Capacity

- Up to 40 pipes/minute Pcs/min

- Printing Speed

- Up to 30 meters/minute mm/m

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Letterpress

- Ink Type

- Special PVC Ink

- Working Temperature

- 5C to 40C Celsius (oC)

- Power

- 3 Phase, 440V, 2.5 kW Volt (v)

- Size

- 10 Inches (Printing Capacity)

- Width

- Adjustable up to 10 inches Inch (in)

- Weight (kg)

- Approx. 650 kg Kilograms (kg)

- Dimension (L*W*H)

- 2500 mm x 900 mm x 1450 mm Millimeter (mm)

10 Inches PVC Pipe Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 2 Units Per Day

- Delivery Time

- 15 Days

- Packaging Details

- Packed in wooden boxes.

- Main Export Market(s)

- Asia, Middle East

About 10 Inches PVC Pipe Printing Machine

Our enterprise has extended its production in the market by providing superior quality PVC Pipe Printing Machine (10 Inch). The offered machine is manufactured at our well-designed production unit using quality-approved components and sophisticated technology under the stern observation of our deft professionals. This machine is used for printing company name, size, logo, batch no., ISI number and others. Furthermore, our respected clients can easily avail this PVC Pipe Printing Machine (10 Inch) in various technical specifications as per their needs at the most reasonable rates.

Features:

- Excellent performance

- Negligible maintenance

- Long service life

- Easy to operate

| Color | Single Color |

| Brand/Make | Laxmi Engineering |

| Model/Type | 10 inch |

| Usage/Application | PVC PIPE PRINTING MACHINE |

| Country of Origin | Made in India |

Advanced Automation and Precision Control

This printing machine features a fully automated system powered by a cutting-edge PLC controller. It reduces manual intervention, allowing users to achieve sharp, consistent prints on every PVC pipe. With precise parameter control, production teams can adapt settings instantly to meet varying order specifications, enhancing workflow efficiency.

Versatile Printing with Industry-Ready Build

Made from strong mild steel, this PVC pipe printing machine is built to withstand industrial demands. Adjustable width support up to 10 inches expands its compatibility with various pipe sizes. The integration of a letterpress plate type and specialized ink guarantees optimal adhesion and clarity, making it suitable for diverse marking needs.

FAQs of 10 Inches PVC Pipe Printing Machine:

Q: How does the PVC Pipe Printing Machine achieve consistent and high-quality prints?

A: The machine uses automatic operation powered by a PLC-based control system. This allows precise management of print parameters, ensuring uniform ink distribution and sharp marking on every PVC pipe, even at high speeds.Q: What materials and dimensions can this PVC pipe printing machine handle efficiently?

A: This equipment is specifically designed for printing on PVC pipes with adjustable widths up to 10 inches. Its robust construction supports pipes of various thicknesses as long as they fit within the specified size and width parameters.Q: When is it optimal to use this machine in production settings?

A: This printer is best used in medium to large-scale pipe manufacturing facilities that require consistent, quick, and clear branding or technical markings. Its automatic features make it especially suitable for continuous production routines.Q: Where is the optimal placement for this machine on a factory floor?

A: Due to its dimensions (2500 mm x 900 mm x 1450 mm) and weight of around 650 kg, it is recommended to install the machine in a dedicated area with a stable power supply (3 Phase, 440V) and sufficient ventilation to keep the ambient temperature between 5C and 40C.Q: What is the process for setting up and operating the machine?

A: After positioning the equipment and connecting it to the appropriate power source, operators program production details via the PLC interface. The machine automatically handles feeding, printing, and output, requiring minimal manual intervention outside of routine maintenance.Q: How does the use of special PVC ink benefit the printing process?

A: Special PVC ink is formulated to ensure strong adhesion to pipe surfaces, resulting in long-lasting markings that withstand environmental factors and handling, crucial for maintaining traceability and compliance standards.Q: What are the key advantages of using this PVC Pipe Printing Machine?

A: The main benefits include increased productivity due to high-speed, automated operation, reliable and repeatable print quality, versatility for various pipe sizes, and durability, thanks to its robust mild steel construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Printing Machines Category

Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Type : Pipe Printing Machine

Material : Mild Steel

Computerized : Yes

Plate Type : Letterpress

Power : 220V / 50Hz / 1.5 kW

PVC Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Type : PVC Pipe Printing Machine

Material : Mild Steel

Computerized : Yes

Plate Type : Other, Rotary Plate

Power : 2.5 kW

One Meter Pipe Printing Machine

Minimum Order Quantity : 1 Piece

Type : One Meter Pipe Printing Machine

Material : Mild Steel

Computerized : Yes

Plate Type : Other, Roller Plate

Power : 220V/50Hz Volt (v)

Hot Embossing Machine

Minimum Order Quantity : as per requirement Unit

Type : Hot Embossing Machine

Material : Mild Steel

Computerized : No

Plate Type : Other, Die Plate

Power : 1.5 kW

Send Inquiry

Send Inquiry