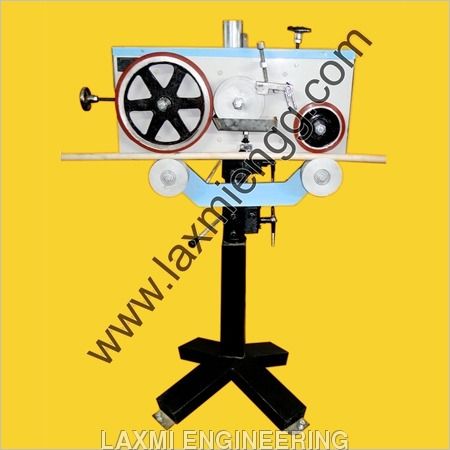

Hot Embossing Machine

Hot Embossing Machine Specification

- Type

- Hot Embossing Machine

- Material

- Mild Steel

- Printing Speed

- 15 m/min

- Computerized

- No

- Plate Type

- Die Plate

- Ink Type

- Foil Ink

- Color Management

- Manual Adjustment

- Control System

- Push Button Control

- Working Temperature

- Up to 250C

- Power

- 1.5 kW

- Size

- Standard

- Width

- 500 mm

- Weight (kg)

- Approx 120 kg

- Dimension (L*W*H)

- 1000 x 500 x 1300 mm

Hot Embossing Machine Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 1 Days

- Packaging Details

- Packed in wooden boxes.

- Main Export Market(s)

- Middle East, Australia, Eastern Europe, North America, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Hot Embossing Machine

To facilitate the entire printing industry, we are manufacturing and exporting to our clients a large stock of HDPE Hot Embossing Marking Machine. All these machines are technically sound in terms of high performance and reliable operations. The offered machines are hugely demanded by the clients for their excellent marking functions required for pipes and cables. Our respected clients can avail the HDPE Hot Embossing Marking Machine at most competitive prices.

Features:

- Trouble free performance

- Easy usage

- Longer service life

Robust Construction and Reliable Performance

Crafted from durable mild steel, the hot embossing machine is designed to withstand demanding production environments. The devices stable build ensures consistent output, making it ideal for suppliers and manufacturers who require longevity and low maintenance from their equipment.

User-Friendly Operation and Versatility

Featuring a manual push button control system, this machine is straightforward to operateeven without computerization. Its standard dimensions allow it to integrate easily into varied production lines, supporting applications across multiple industries.

FAQs of Hot Embossing Machine:

Q: How does the hot embossing machine operate without computerization?

A: This machine runs entirely with manual controls using an easy-to-handle push button system. Operators adjust settings like color management and temperature by hand, enabling straightforward operation while minimizing technical complications.Q: What materials can be embossed using this machine?

A: The machine is versatile and compatible with various substrate materials suitable for die plate embossing, as long as they can tolerate the working temperature of up to 250C.Q: When should I consider using foil ink with this hot embossing machine?

A: Foil ink is ideal for applications requiring luxuriant, metallic finishes or high-impact visual effects. It is commonly used in decorative packaging, labels, and branding products.Q: Where is this hot embossing machine manufactured and supplied from?

A: This model is manufactured, supplied, and exported from India, serving a variety of domestic and international industrial sectors.Q: What is the basic process for embossing with this machine?

A: The process involves preparing a custom die plate, inserting foil ink, setting the required temperature (up to 250C), and then running material through the machine at your chosen speed. The heat and pressure from the die plate transfer the foil design onto the material.Q: How does manual color management work on this machine?

A: Color is adjusted by hand, allowing users to fine-tune the appearance and quality of the embossed image according to job specifications and preferences.Q: What are the main benefits of using this hot embossing machine?

A: Key benefits include robust mild steel construction, user-friendly manual controls, a reliable standard size for diverse needs, and efficient production speedsmaximizing productivity for manufacturers and exporters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

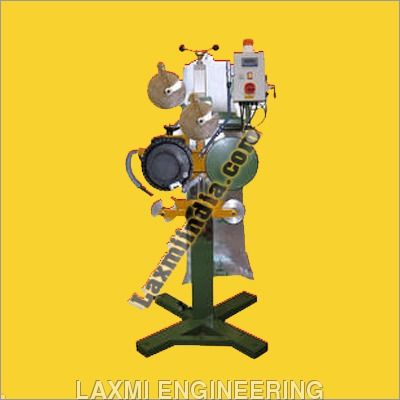

More Products in Pipe Printing Machines Category

Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Width : 650 mm

Material : Mild Steel

Size : Medium Scale

Dimension (L*W*H) : 2100 x 650 x 1500 mm

10 Inches PVC Pipe Printing Machine

Price 50000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Width : Adjustable up to 10 inches Inch (in)

Material : Mild Steel

Size : 10 Inches (Printing Capacity)

Dimension (L*W*H) : 2500 mm x 900 mm x 1450 mm Millimeter (mm)

Double CPVC Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Width : Adjustable (as per pipe size)

Material : Mild Steel

Size : Standard

Dimension (L*W*H) : 2500 x 950 x 1250 mm

One Meter Pipe Printing Machine

Price 52000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Width : Adaptable Up to 120 mm Pipe Millimeter (mm)

Material : Mild Steel

Size : Compact

Dimension (L*W*H) : 2200 mm x 800 mm x 1300 mm Millimeter (mm)

Send Inquiry

Send Inquiry