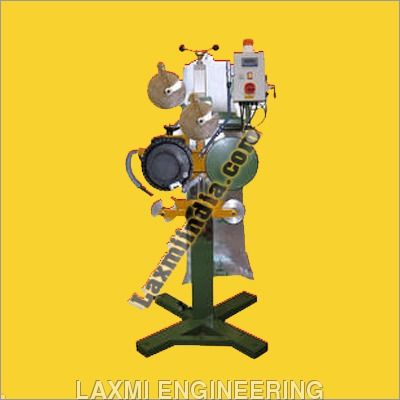

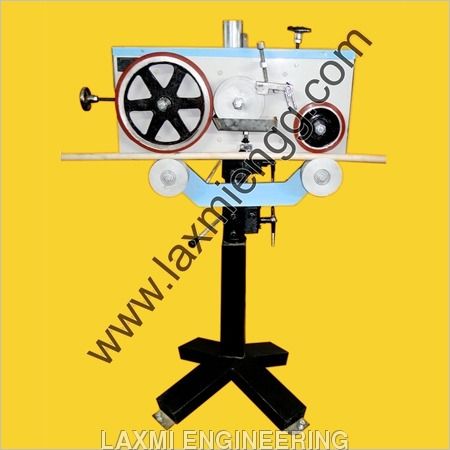

One Meter Pipe Printing Machine

Price 52000.0 INR/ Piece

One Meter Pipe Printing Machine Specification

- Type

- One Meter Pipe Printing Machine

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Roller Plate

- Ink Type

- Quick Drying Ink

- Color Management

- Single Color

- Working Temperature

- 10C to 40C Celsius (oC)

- Power

- 220V/50Hz Volt (v)

- Size

- Compact

- Width

- Adaptable Up to 120 mm Pipe Millimeter (mm)

- Weight (kg)

- Approx. 400 kg Kilograms (kg)

- Dimension (L*W*H)

- 2200 mm x 800 mm x 1300 mm Millimeter (mm)

One Meter Pipe Printing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- Piece

- Delivery Time

- 1-2 Days

- Packaging Details

- Packed in wooden boxes.

- Main Domestic Market

- All India

About One Meter Pipe Printing Machine

We are amid several other enterprises as the foremost manufacturer, exporter and supplier of One Meter Pipe Printing Machine. This machine is manufactured under the strict guidance of our skilled professionals using superior quality components and pioneering technology in sync with market quality standards. The provided machine is extensively used in various informations on pipes. Moreover, our offered One Meter Pipe Printing Machine can be availed by our esteemed clients at a very reasonable rate.

Features:

- Rugged design

- Optimum performance

- Enhanced service life

-

Low maintenance

| Color | Single Color |

| Capacity | 1200m/hr |

| Usage/Application | For Pipe Printing |

| Frequency | 50 Hz |

| Voltage | 380 V |

| Automatic Grade | Semi-Automatic |

| Material | Mild Steel and Plastic |

Advanced Printing Solutions for Mild Steel Pipes

This One Meter Pipe Printing Machine is engineered specifically for manufacturers demanding high accuracy and automation. With customizable settings and efficient single color output, it responds to the diverse needs of the pipe manufacturing sector. Its robust construction and PLC-based computerized control enable dependable performance across a wide temperature range.

Comprehensive Color Management and Ink Technology

Utilizing quick drying ink, this printing machine ensures crisp and smudge-free results, significantly minimizing downtime between production cycles. The color management system supports consistent, vivid marking on pipes, which is essential for industry compliance and product traceability.

FAQs of One Meter Pipe Printing Machine:

Q: How does the One Meter Pipe Printing Machine operate automatically?

A: The machine uses a PLC control system that automates the printing process. Operators can simply input the required parameters, and the machine handles the restfrom feeding and aligning the pipe to applying the print accurately using its roller plate design.Q: What materials and pipe sizes can this printing machine handle?

A: This machine is designed for pipes made of mild steel and can accommodate pipe widths up to 120 mm. Its adaptable mechanism provides flexibility for varying diameters within the one meter pipe length.Q: When is routine maintenance recommended for optimal performance?

A: Routine maintenance should be carried out as per the manufacturers guidelines, typically after every major production cycle or monthly. Regular checks ensure consistent ink flow, clean rollers, and optimal PLC system function.Q: Where is the One Meter Pipe Printing Machine manufactured and supplied from?

A: This machine is manufactured, exported, and supplied from India, making it accessible to a range of international and domestic markets.Q: What is the process for using the machine for pipe printing?

A: Operators load the pipe, configure settings via the computerized interface, and start the automatic print cycle. The machine aligns the pipe and prints using quick drying ink, providing efficient, high-quality results throughout production.Q: What are the main benefits of using this printing machine in pipe manufacturing?

A: Key benefits include fast and precise marking, reduced manual labor, minimized errors, and the ability to maintain consistent branding or identification on every pipe, increasing overall production efficiency and traceability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Printing Machines Category

10 Inches PVC Pipe Printing Machine

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Size : 10 Inches (Printing Capacity)

Width : Adjustable up to 10 inches Inch (in)

Power : 3 Phase, 440V, 2.5 kW Volt (v)

Computerized : Yes

Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Material : Mild Steel

Size : Medium Scale

Width : 650 mm

Power : 220V / 50Hz / 1.5 kW

Computerized : Yes

PVC Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Material : Mild Steel

Size : Standard

Width : 600 mm

Power : 2.5 kW

Computerized : Yes

Hot Embossing Machine

Minimum Order Quantity : as per requirement Unit

Material : Mild Steel

Size : Standard

Width : 500 mm

Power : 1.5 kW

Computerized : No

Send Inquiry

Send Inquiry