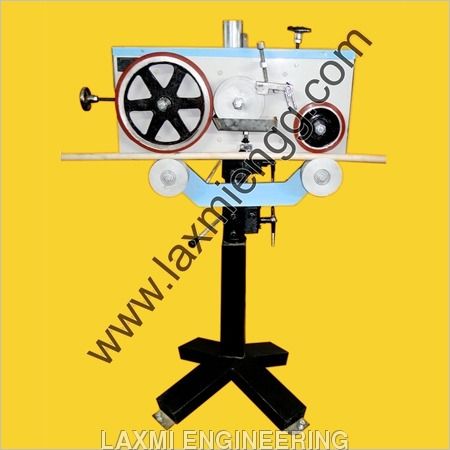

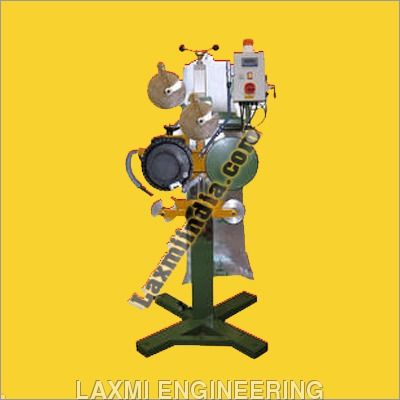

Single Pipe Printing Machines

Single Pipe Printing Machines Specification

- Type

- Single Pipe Printing Machine

- Material

- Mild Steel

- Capacity

- High (Depends on model and requirement)

- Computerized

- No

- Plate Type

- Rotary

- Color Management

- Manual Adjustment

- Control System

- PLC Based / Manual

- Working Temperature

- 0C to 45C

- Power

- 220V / 380V, 3 Phase

- Size

- Standard / Customizable

- Width

- Adjustable as per pipe size

- Weight (kg)

- Approx. 350 kg

- Dimension (L*W*H)

- 2500 mm x 700 mm x 1400 mm

Single Pipe Printing Machines Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 1 Days

- Packaging Details

- Packed in wooden boxes.

- Main Domestic Market

- All India

About Single Pipe Printing Machines

Our firm has gained prominent niche with the specialized domain of manufacturing and supplying a large stock of Single Pipe Printing Machines. These machines are specifically engineered by our engineers in different size specifications of 6 Inch, 20 mm x 100 mm. Further, our offered machines have the capacity to print seven impressions on the pipes ranging 20mm to 250mm. The offered Single Pipe Printing Machines are used for providing license, ISI mark, license & batch number and logo printing purpose.

Features:

- High operational fluency

- Quality certified

- Require less maintenance

Versatile Printing Solutions for Pipes

This machine is designed to print clearly and efficiently on pipes of different sizes and types. Thanks to its adjustable width and customizable options, users can tailor their printing process to meet specific project requirements. With its robust construction, this equipment is built to withstand demanding manufacturing conditions, ensuring reliable performance on a daily basis.

Flexible Manual and PLC-Based Operation

Operators can choose between manual and PLC-based control systems depending on their workflow and automation needs. Color management is done manually, offering flexibility in print customization. This flexibility allows both experienced and new users to achieve optimal print results according to production demand.

FAQs of Single Pipe Printing Machines:

Q: How does the Single Pipe Printing Machine operate without computerization?

A: The machine is engineered for ease-of-use and requires manual operation, supported by a PLC-based or fully manual control system. Operators use the manual controls or PLC interface to set printing parameters, adjust the rotary plate, and manage color settings, ensuring precise print application on pipes.Q: What types of pipes can this machine accommodate?

A: Our machine is suitable for printing on pipes made from various materials, provided the pipe fits within the adjustable width and standard or customized size options. The adjustable design allows for flexibility when handling pipes of varying diameters.Q: When is a PLC-based system preferred over manual operation?

A: A PLC-based control system is recommended for higher production rates or when consistent print quality and repeatability are required. For smaller batches or when greater manual control is needed for custom jobs, manual operation is a suitable alternative.Q: Where can this pipe printing machine be installed?

A: This equipment is designed to serve manufacturers, suppliers, and exporters across India and can be installed in industrial workshops, manufacturing plants, or any facility with the specified power supply and adequate space for its dimensions.Q: What is the process of printing with this machine?

A: Pipes are loaded onto the machine, where the adjustable width settings secure them in place. The rotary plate applies printing as the pipe rotates beneath it. Operators set up color management manually and control the process via the chosen control system. The workflow is designed for efficiency and repeatable results.Q: How is maintenance handled for the machine?

A: Routine cleaning of the printing mechanism, periodic checks of the rotary plate, and inspection of electrical connections ensure smooth operation. Maintenance requirements are minimal due to the durable mild steel construction, but regular attention helps maintain long-term reliability.Q: What are the main benefits of using this single pipe printing machine?

A: Key benefits include high-capacity output, customization for various pipe dimensions, robust performance across a broad temperature range (0C to 45C), manual flexibility, and a sturdy build crafted from mild steel. These features make it an ideal solution for efficient, high-quality pipe marking and labeling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Printing Machines Category

10 Inches PVC Pipe Printing Machine

Price 50000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 2500 mm x 900 mm x 1450 mm Millimeter (mm)

Weight (kg) : Approx. 650 kg Kilograms (kg)

Ink Type : Other, Special PVC Ink

Material : Mild Steel

PVC Pipe Printing Machine

Minimum Order Quantity : as per requirement Unit

Dimension (L*W*H) : 2200 mm x 600 mm x 1400 mm

Weight (kg) : Approx. 400 kg

Ink Type : Other, Solvent Based Ink

Material : Mild Steel

One Meter Pipe Printing Machine

Price 52000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 2200 mm x 800 mm x 1300 mm Millimeter (mm)

Weight (kg) : Approx. 400 kg Kilograms (kg)

Ink Type : Other, Quick Drying Ink

Material : Mild Steel

Hot Embossing Machine

Minimum Order Quantity : as per requirement Unit

Dimension (L*W*H) : 1000 x 500 x 1300 mm

Weight (kg) : Approx 120 kg

Ink Type : Other, Foil Ink

Material : Mild Steel

Send Inquiry

Send Inquiry